Fossil Fuels

Fossil Fuels

especially solar. Need to store the

excess energy when the collector system is being irradiated

especially solar. Need to store the

excess energy when the collector system is being irradiated

Generating stations operate more efficiently

if they run at constant output level

Generating stations operate more efficiently

if they run at constant output level  want to shove unused

energy to a storage system and recover it later at times of peak

demand.

want to shove unused

energy to a storage system and recover it later at times of peak

demand.

14

14

0.04

0.04

0.3 (per cubic meter)

0.3 (per cubic meter)

0.05

0.05

0.2

0.2

0.9

0.9

38

38

2 (per cubic meter)

2 (per cubic meter)

Energy density storage drives the choices that can be made:

Pumped Hydroelectric Energy Storage:

use excess energy to pump water uphill

use excess energy to pump water uphill

pump from lower reservoir (natural or artifical) to upper

reservoir.

pump from lower reservoir (natural or artifical) to upper

reservoir.

Energy recovery depends on total volume of water and its height above the turbine

this is a stringent limit

on locations

this is a stringent limit

on locations

can achieve higher energy density due to large vertical distance

(up to 1000 feet!)

can achieve higher energy density due to large vertical distance

(up to 1000 feet!)

Cost Issues:

Suppose a company has a coal fired plant which operates at 36% efficiency and uses excess power to pump water uphill. The overall efficiency of recovering that to deliver to the consumer is 0.36 x 0.64 = 0.23 (23%)

what's the incentive?

what's the incentive?

Real Life Facility in Michigan

A flywheel, in essence is a mechanical battery - simply a mass rotating about an axis. Flywheels store energy mechanically in the form of kinetic energy. They take an electrical input to accelerate the rotor up to speed by using the built-in motor, and return the electrical energy by using this same motor as a generator.Flywheels are one of the most promising technologies for replacing conventional lead acid batteries as energy storage systems.

So, in other words. During times that your

generating more power than you need, you can spin the fly wheel up,

so to speak. When you need to recover that energy, you let the fly wheel

spin down.

To optimize the energy-to-mass ratio the flywheel needs to spin at

the maximum possible speed. This is because kinetic energy

only increases linerarly with Mass but goes as the square of

the rotation speed.

Rapidly rotating objects are subject to centrifugal forces that can

rip them apart.

Thus, while dense material can store more energy it is also subject

to higher centrifugal force and thus fails at lower rotation speeds

than low density material.

Tensile Strength is More important than density of material.

Long rundown times are also required Flywheels are about 80% efficient (like hydro)

Flywheels do take up much less land than pumped hydro systems

The model with the small yellow disc

tends to stop when the crank and

connecting rod are in a straight line

('dead' spots) - because sliding the

brass knob exerts no turning force on

the shaft.

In the model with the big yellow

flywheel, it is easy to keep the disc

turning, once it has started, due to the

effect of the flywheel.

The mass and the size of the big

flywheel helps resist the slowing down

of the model as it is turning.

Comparative Advantages/Disadvantages of high speed flywheels

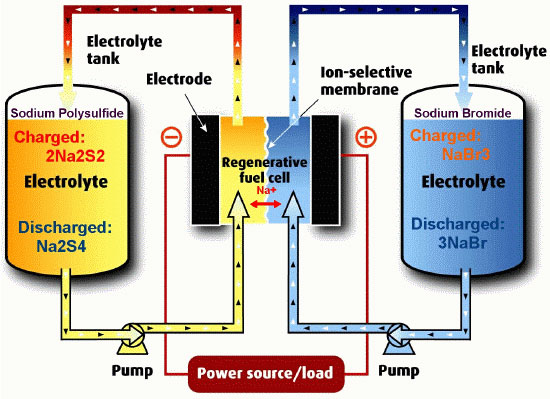

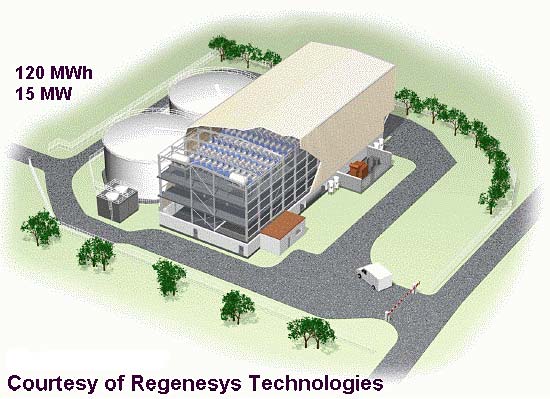

Flow Batteries:

Excitement over flow batteries derives from their attributes, which combine aspects of conventional batteries and fuel cells. They are relatively

simple, efficient, scalable, durable, and can optimize either power or energy output, as desired. Flow batteries can respond in fractions of a second and can cycle rapidly and deeply at high or low power output with minimal battery degradation.

Flow batteries are scalable from a few watts and kilowatt-hours to tens or hundreds of megawatts and megawatt-hours.

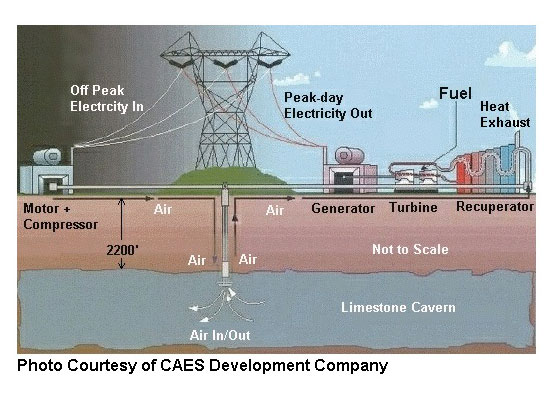

Compressed Air:

Has high energy storage capacity compared to the alternatives.

About 10 times higher per cubic meter than water.

One example (in Germany) to date:

Ultracapacitors

ultracapacitors pack up to

100 times the energy of conventional

capacitors and deliver ten times the

power of ordinary batteries.

An application:

frictionless bearings and

a vacuum to minimize air resistance can result in rundown times of

6 months

frictionless bearings and

a vacuum to minimize air resistance can result in rundown times of

6 months  steady supply of energy

steady supply of energy

High tensile strength material allows it

to be rotated very fast without flying apart

High tensile strength material allows it

to be rotated very fast without flying apart

this is a critical requirement (see below)

this is a critical requirement (see below)

New Technology:

ultracapacitors are a new

energy storage technology ideally suited

for applications needing repeated bursts

of power for fractions of a second to

several minutes.

New Technology:

ultracapacitors are a new

energy storage technology ideally suited

for applications needing repeated bursts

of power for fractions of a second to

several minutes.

Energy Storage for Prototype Military Transport

Vehicle powered by Hybrid Electric Drive System