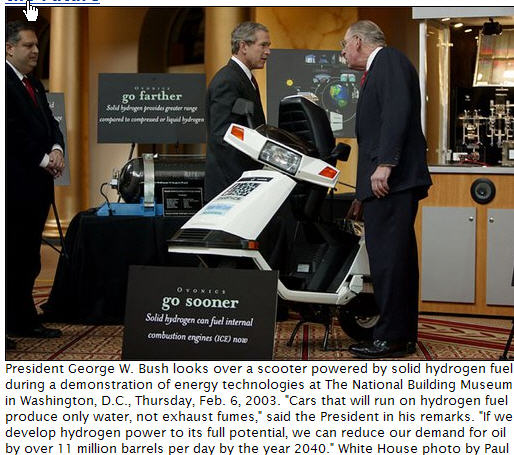

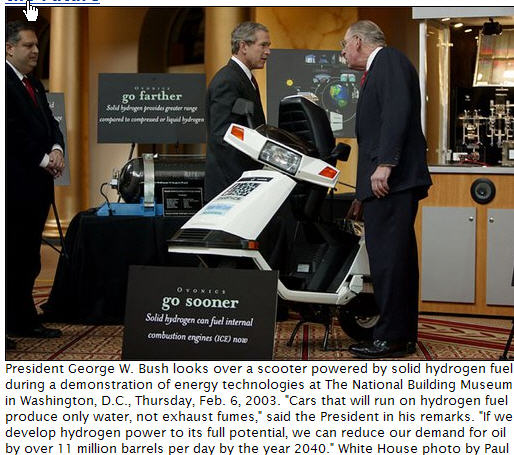

The Coming Hydrogen Economy?

This will only be scalable if we are clever enough to use dedicated renewable energy to produce hydrogen in situ, rather than grid connected power at those dedicated locations |

Ultimate Green Power?

Ultimate Green Power?

The benefits of a hydrogen economy, relative to the current situation are large!

duh ... But, we just might

be sufficiently stupid to use Fossil Fuels to produce hydrogen in keeping with our style

over substance traditions ...

duh ... But, we just might

be sufficiently stupid to use Fossil Fuels to produce hydrogen in keeping with our style

over substance traditions ...

No shit Sherlock ...

No shit Sherlock ...

Internal-combustion engines in today's automobiles convert less than 30 percent of the energy in gasoline into power that moves the vehicle. Vehicles using electric motors powered by hydrogen fuel cells are much more energy efficient, utilizing 40-60 percent of the fuel's energy.

Barriers to achieving this Future:

In addition, the current system for delivering conventional fuels to consumers cannot be used for hydrogen. Many expensive changes must be made in our nation's energy infrastructure to accommodate hydrogen.

so Tax gasoline and use the revenue to make these investments!

So, a 15 gallon gas tank that contains 90 pounds of gasonline would need to be 60 gallons

containing 34 pounds of hydrogen

High-pressure storage tanks are currently being developed, and research is being conducted into the use of other storage technologies such as metal hydrides and carbon nanostructures (materials that can absorb and retain high concentrations of hydrogen).

This is an engineering and materials development problem which can be

solved

In addition, all fuel cells are prone, in varying degrees, to catalyst poisoning, which decreases fuel cell performance and longevity.

Production of Hydrogen.

Cost is the biggest impediment to using hydrogen more widely as a fuel. Hydrogen is currently more expensive to produce than conventional fuels, such as gasoline, and many of the more cost-effective production methods generate greenhouse gases.

Cost is the biggest impediment to using hydrogen more widely as a fuel. Hydrogen is currently more expensive to produce than conventional fuels, such as gasoline, and many of the more cost-effective production methods generate greenhouse gases.  Hydrogen has low volumetric energy density. This

makes it difficult to store enough energy in a reasonably sized space. This is a particular problem for hydrogen-powered fuel cell vehicles, which must store hydrogen in compact tanks.

Hydrogen has low volumetric energy density. This

makes it difficult to store enough energy in a reasonably sized space. This is a particular problem for hydrogen-powered fuel cell vehicles, which must store hydrogen in compact tanks.

38

38

14

14

0.04

0.04

this means that for the near future,

hydrogen powered cars are not practical, but trucks and busses are very practical.

this means that for the near future,

hydrogen powered cars are not practical, but trucks and busses are very practical.

This is required for the Hydrogen

Economy to Exist  High-temperature fuel cells, in particular, are prone to material breakdown and shortened operating lifetimes. PEM fuel cells must have effective water management systems to operate dependably and efficiently.

High-temperature fuel cells, in particular, are prone to material breakdown and shortened operating lifetimes. PEM fuel cells must have effective water management systems to operate dependably and efficiently.

This animation shows the process that goes on inside an individual fuel cell. The red Hs represent

hydrogen molecules (H2) from a hydrogen storage tank. The orange H+ represents a hydrogen ion

after it's electron is removed. The yellow e- represents an electron moving through a circut to do

work (like lighting a light bulb or powering a car). The green Os represent an oxygen molecule (O2)

from the air, and the blue drops at the end are for pure water--the only byproduct of hydrogen

power.

needed to ensure safety, as well as to commercialize hydrogen as a fuel.

needed to ensure safety, as well as to commercialize hydrogen as a fuel.

can extant gas stations be retrofitted

with hydrogen "pumping" facilities?

can extant gas stations be retrofitted

with hydrogen "pumping" facilities?

About 95% of the hydrogen we use today comes from reforming natural gas. The remainder, high-purity hydrogen from water electrolysis, is produced using electricity mainly generated by burning fossil fuels.

We can do much better than this by more fully utilizing the following techniques:

so all you need to make hydrogen is electricy and water. Well hell, let's start making it

everywhere you can put a wind turbine.

so all you need to make hydrogen is electricy and water. Well hell, let's start making it

everywhere you can put a wind turbine.

Steam electrolysis utilizes high temperature heat to reduce electricity requirements for hydrogen production  an excellent geothermal use

an excellent geothermal use

may be practical in very sunny remote locations if

you can find water

may be practical in very sunny remote locations if

you can find water

probably does not have the yield potential of other forms of production.

probably does not have the yield potential of other forms of production.

In principle, you could use a wind farm to make X number of liters of liquified Hydrogen or

X number of KG of hydrogen on site. You could then transport that hydrogen, someway, to

individual houses, and recover 90% of the KWHs that went in to producing it.  This is cheaper than trying to build a 1000 km transmission line from a wind farm to

an urban area.

This is cheaper than trying to build a 1000 km transmission line from a wind farm to

an urban area.

Once standards are developed for handling and distributing hydrogen, the industry is going to wake up to this financial reality.

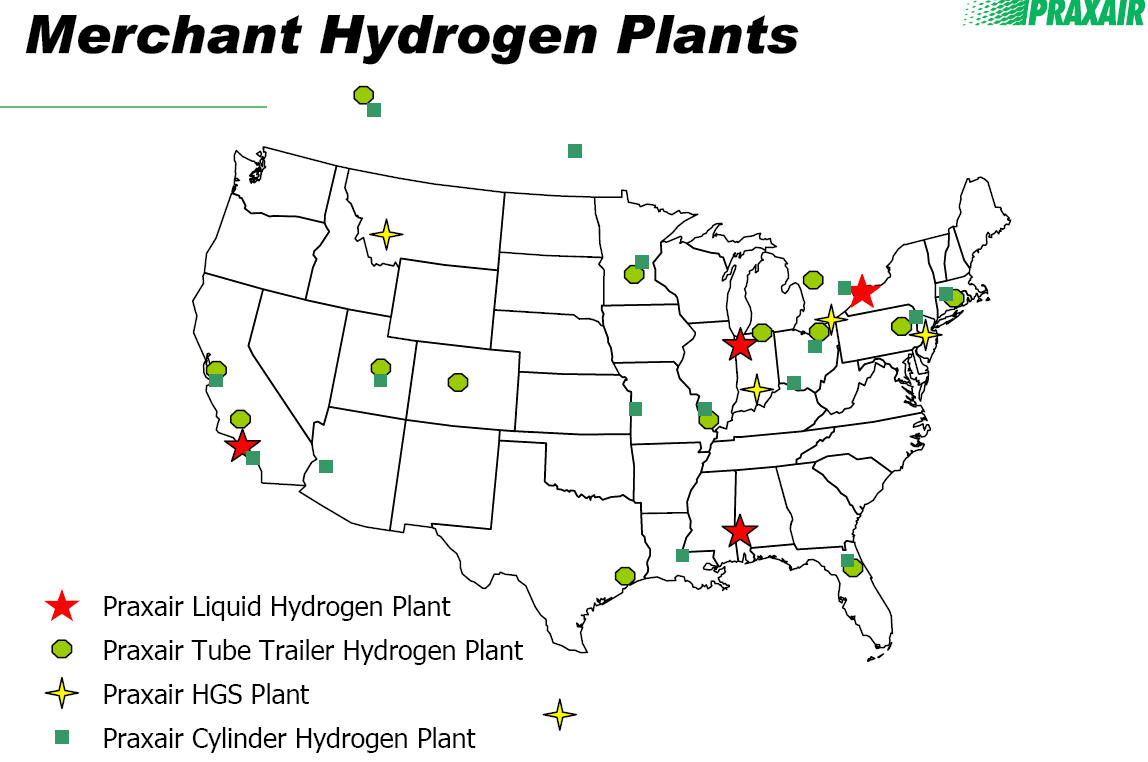

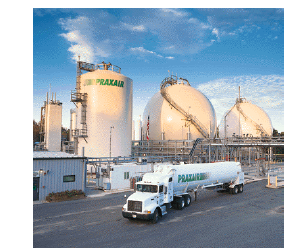

Some infastructre already exists:

< Bottom Line: All of this is possible, but it will take 20 years of steady investment in compression technology, hydrogen distribution facilities and dedicated hydrogen production sites. It can be done. Will it be done?