The Importance of Supply Chains in the Real World

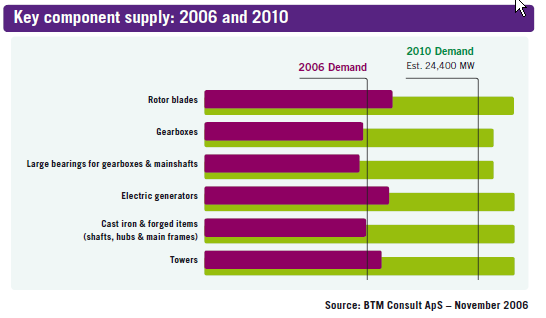

Supply chains determine the rate at which a product can be delivered or installed. The timescale is ultimately determined by the longest component production timescale in the supply chain. The longer the supply chain, the higher the probability of being rate limited.

Wind Energy:

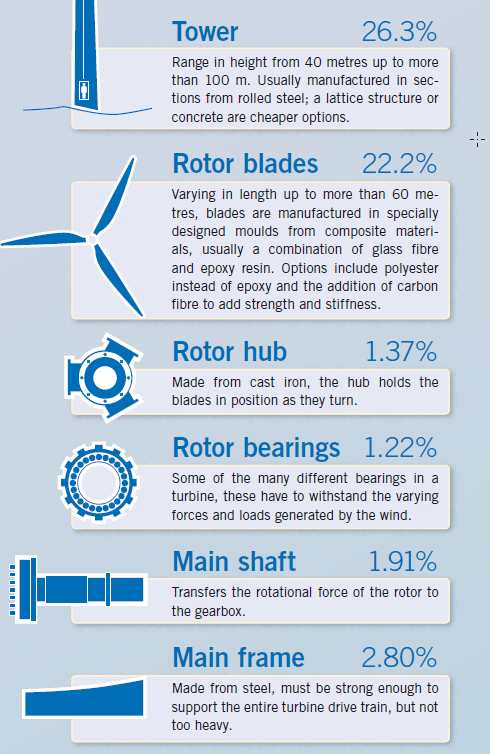

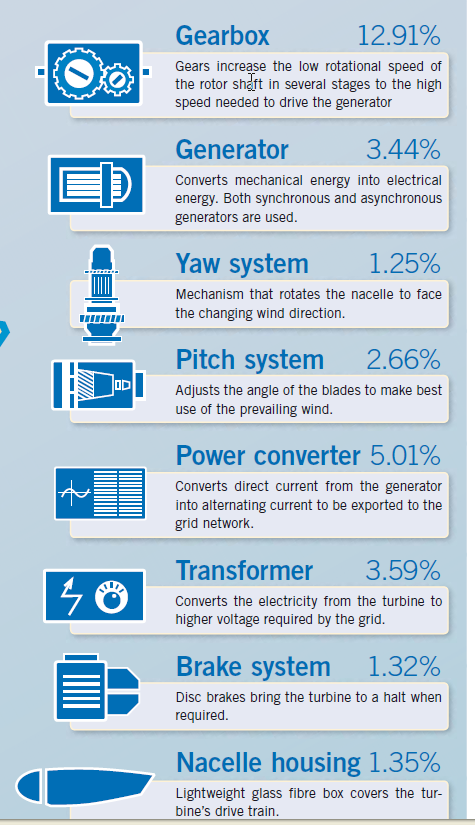

In simple terms, a

wind turbine consists of a rotor that

has wing shaped blades attached to a

hub; a nacelle that houses a drivetrain

consisting of a gearbox, connecting

shafts, support bearings, the generator,

plus other machinery; a tower; and

ground-mounted electrical equipment.

In simple terms, a

wind turbine consists of a rotor that

has wing shaped blades attached to a

hub; a nacelle that houses a drivetrain

consisting of a gearbox, connecting

shafts, support bearings, the generator,

plus other machinery; a tower; and

ground-mounted electrical equipment.

Different vendors make different parts.

- Blades plus nose (Vestas)

- Generators (Detroit Retrofits)

- Nacelle + Gearboxes (Vestas, Siemes)

- Towers (contract to any Iron works)

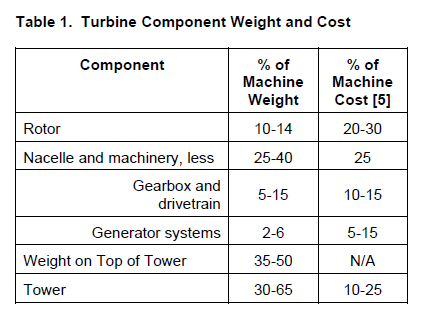

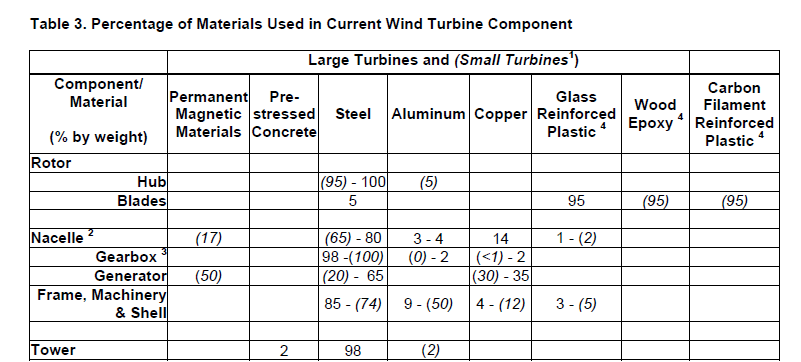

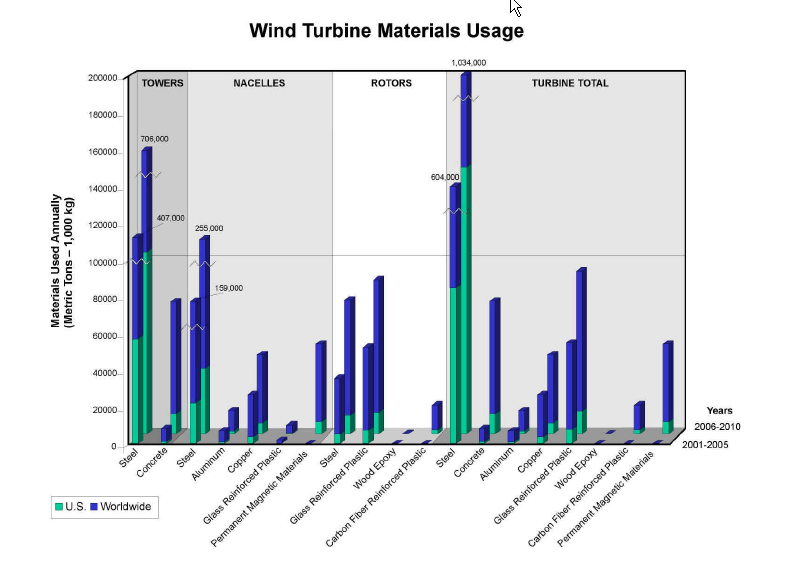

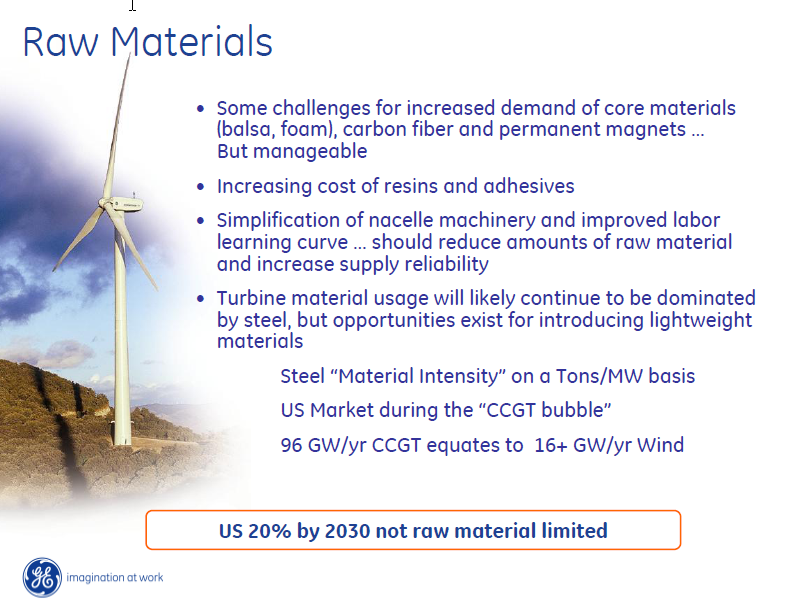

Material required in the supply chain:

Some Observations:

- Turbine material usage is and will continue to be dominated by steel, but opportunities exist

for introducing aluminum or other light weight composites, provided strength and fatigue

requirements can be met.

- Elimination of the gearbox by using

variable speed generators will increase through use of

permanent magnetic generators on larger turbines increasing the need for magnetic materials.

- Simplification of the nacelle machinery may not only reduce costs, but also increase

reliability. Currently, gearbox failure is the biggest problem for Wind Turbines.

- Blades are primarily made of GRP, which is expected to continue. Increased use of CFRP may

help to reduce weight and cost.

- Prestressed concrete towers are likely to be used more, but will need a substantial amount of

steel for reinforcement.

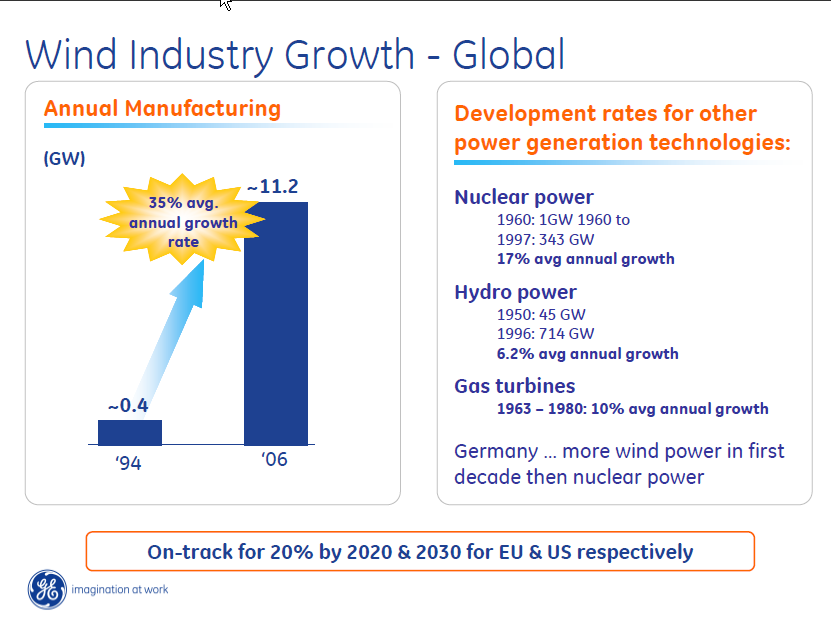

- Wind turbine component and materials manufacturing are major and expanding business opportunities for at least the next 20 years.

8 x 1.5 MW x 365 = 4400 MW per year (or a coal fired nameplate capacity replacement time of 100 years)

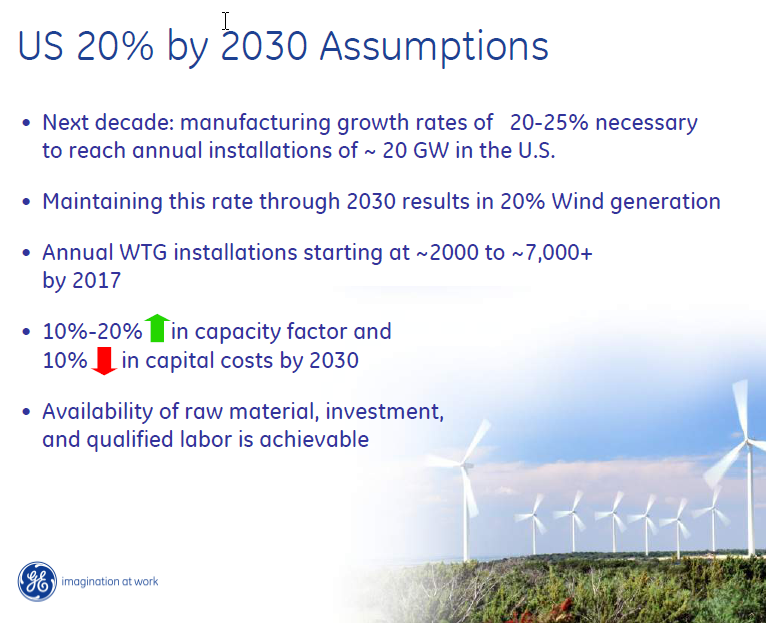

35% average growth is impressive but ultimately requires commensurate growth in all supply chain sectors.

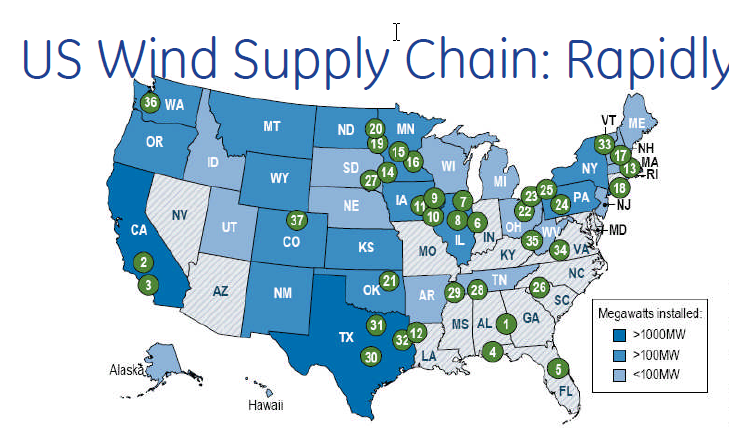

Bottom line here is that Wind energy is driven by a materials supply chain which

ultimately involves individual manufacturing sites and component integration.

In addition to supply chain considerations, there is the increasingly recognized

importance of the Energy Payback Timescale.

This is the timescale over which the total supply chain energy of manufacturing

is paid back by harvested energy from the device. This is a difficult calcuation

to make but as it stands now.

The Big bottom line here is that, in every way measureable, Wind is more scalable

than Solar PV.