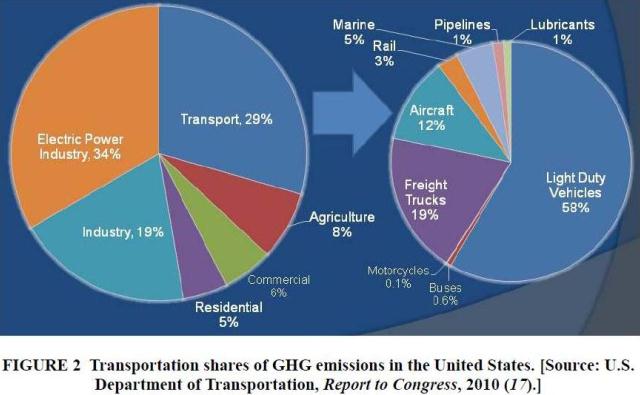

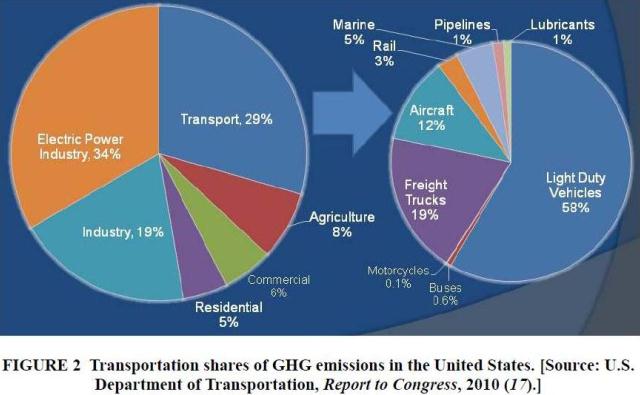

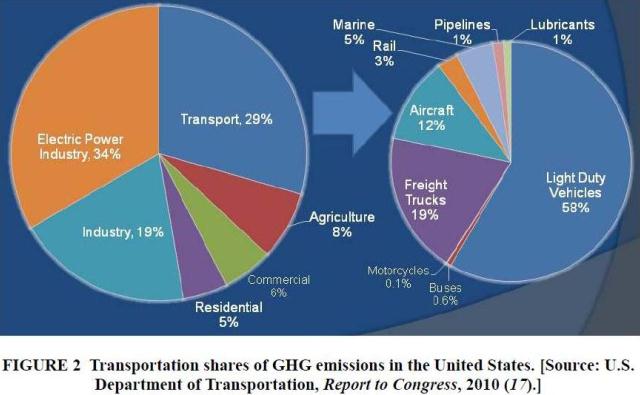

The overall transportation foot print on greenhouse gas

emission is relatively large. In the United States it has long been the case that transportation related emissions are about equal to electricity related emissions. Futhermore, the bulk

of the transportation related emissions come from single passenger light duty vehicle traffic:

To mitigate this, any public policy aimed at reducing gasoline consumption would be wise. There are basically three possible ways to achieve this:

- Tax gasoline so that its sufficiently expensive to encourage conservation. Such a tax would likely be grossly unfair to the working poor.

- Get serious about fuel economy - why not have aggressive goals to reach 50 mpg by 2020? Note this would mean that our culture would have to accept driving around in smaller mass vehicles.

- Ramp up alternative fuel sources: such sources include batteries (Li-Ion), biodiesel, ethanol, and hydrogen. The feasibility of these alternative fuels are discussed in more detail below

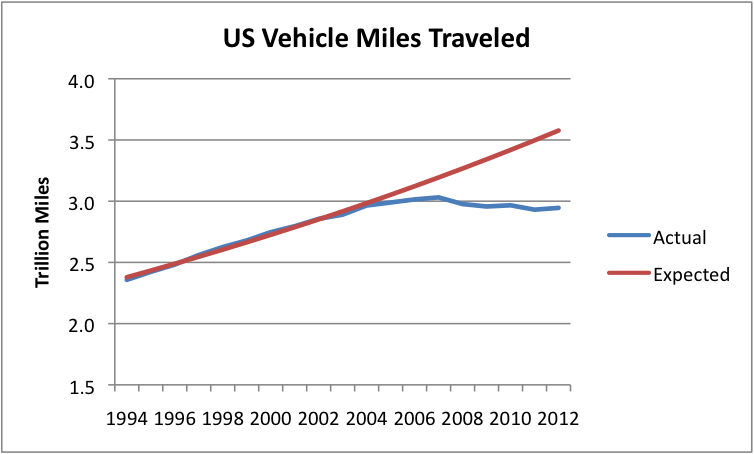

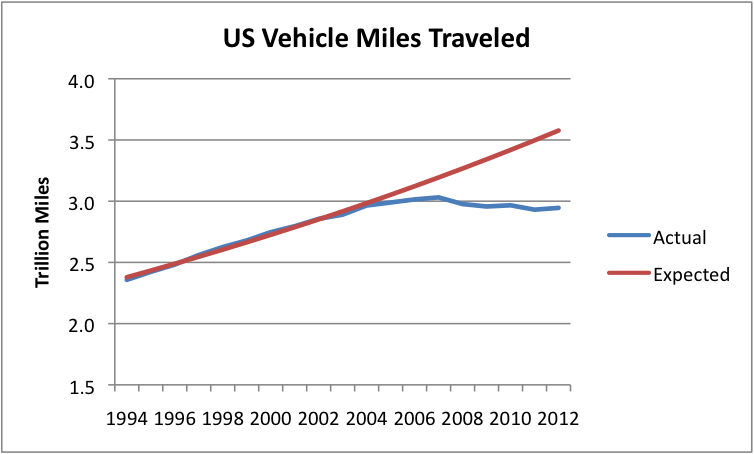

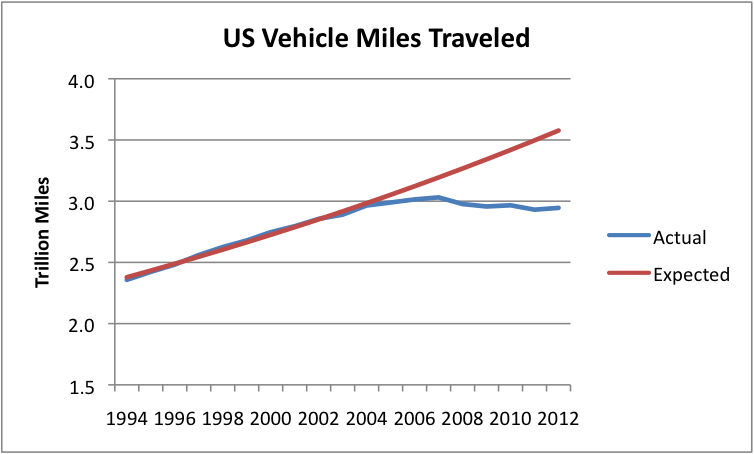

In recent years, American driving habits have slightly changed due to a combination of small increases (about 20%) in fuel

efficiency for new cars and the perceived high price of gasoline.

We are no longer driving increasingly more each year and appear

to have, for now, levelled off. However, this levelling off is still fairly small (20% less than linear prediction) and the absolute amount of miles driven remains very large and thus

gasoline consumption and ghg emissions from that consumption

is also large (see below).

In April 2013, the US consumed 8766 thousand barrels of

Gasoline per day

There are 42 gallons per barrel and this then equates to the

368 million gallons of gas used per day! The all time record

was set in July 2007 at 404 millions of gallons per day.

Thus the consumption scale is very large and the issue becomes, one of scalability among various alternative fuel sources - can any of them come close to 400 million gallons per day (~150 BILLION gallons per year)?

Any alternative has to scale to these production and distribution amounts

for that alternative to be scalable and hence feasible.

Alternatives that can't scale represent only niche solutions. If there are many many niche solutions, then an integrated solution can bet stitched together. But in the case of alternatives

to gasoline for transport fuel, there are only a few possibilities.

Below we evaluate various alternatives in terms of their

potential scalability:

- Biodiesel:

Biodiesel is a domestically produced, renewable fuel

that can be manufactured from vegetable oils,

animal fats, or recycled restaurant greases.

Highest yields come from:

It takes about 7.3 pounds of soybean oil to produce one gallon of biodiesel. Current soybean costs are 47 cents per pound.

$3.43 for a gal which costs about 20 cents per pound, Feedstock costs

alone, therefore, are at least $3.40 per gallon of soy

biodiesel, comparable to the current price of gasoline.

Total possible yield:

- There are about 360 million acres of usable crop land in the US.

- One acre of land produces an average of 40 bushels of soybeans.

- Each bushel of soybeans can produce about 1.5 gallons of soybean oil.

- Efficiency of conversion of soybean oil to right chemical formula for

fuel in an engine: about 80%

Multiplying everything together gets you 18 billion gallons a year (remember

we need 150) and this would require all crop land devoted to growing fuel

and not food for a resultant 12% market penetration.

The figure below show the potential future biofuels industry in the US where it can be seen that BioDiesel remains a niche fuel

and that most of the growth occurs in the area of cellulosic ethanol (discussed in the next lecture in detail).

- Electricity (e.g. Plugin Hybrid Electric Vehicles - PHEV or straight EVs)

Note, one of the principle issues here is the scalability of the Lithium Ion supply chain. The issue of a possible Lithium

shortage can be found HERE

Independent of whether there will be a physical resource shortage

of Lithium, the rate of replacement of gasoline powered cars is

an issue in the US and worldwide.

New Car production in the US has now rebounded from the economic

slow down and now stands at 13-14 million new vehicles produced

per year:

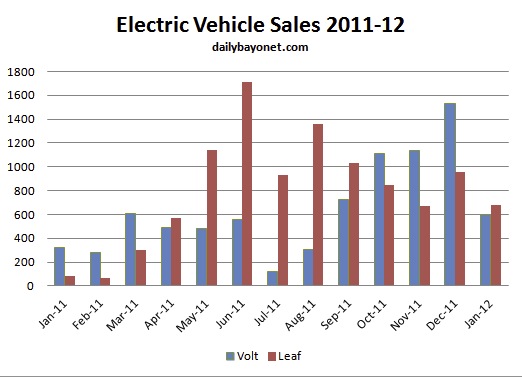

By contrast, current US sales of the Nissan Leaf and Chevy Volt

average, at most, 1000 units per month; 12,000 EVs out of 14 million is very small (note: this does not include PHEVs).

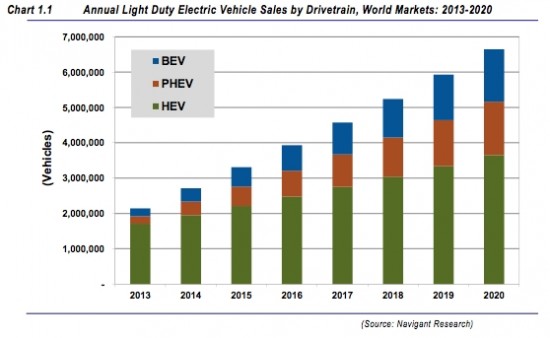

On a worldwide basis, sales of PHEVs (plug-in Hybrid Electrical

Vehicles) are expected to increase but ultimately this represents

only 3% of the global vehicle market by the year 2012. Note that BEV = Battery Electrical Vehicle (or pure EV). The reason for

this low market penetration is a) Lithium is not presently scalable to

worldwide demand and b) the actual manufacturing of battery packs

is a very slow process. For instance, in the first year (2010) of the introduction of the Leaf, only 10,000 were made for the US market. You just can't make battery packs very fast.

A brief primer on important numbers for EV calculations:

- You will see numbers ranging from 33 to 37 KWH energy equivalent to a gallon of gasoline.

The variation is related to whether you do the calculation by mass or by volume since the

volume of gallon of gas is temperature dependent. In round numbers there are 35 KWH per gallon of

gas.

- Suppose average fuel economy rises to 35 miles per gallon (for a 3000 lb car)

This is

then equivalent to 1 KWH per mile energy cost. This is a useful number to know. This is

then equivalent to 1 KWH per mile energy cost. This is a useful number to know.

- But, an electric motor is about 2.8 times more efficient than an ICE and therefore

the per mile electricity cost equivalent is about 0.35 KWH per mile.

- A lithium-ion battery pack currently stores an average of 140 watt hours per kg. Typical laptop battery

weighs about 1 kg and average laptop power consumption is about 40 watts. This means

your laptop battery lasts for 140 watt hours/40 watts = 3.5 hours. At peak power/screen brightness your laptop

likely consumes 80 watts and so the battery lifetime would he halved.

- Suppose you want 100 mile free range (such as the Nissan leaf "claims") on your lithium-ion

battery pack. @0.35 KWH per mile you would then need to store 35 KWH of electricity: @140

watt hours per kg (.14 KWH per kg) you would need 35/.14 = 250 kg (550 lb) battery pack -

a significant fraction of total vehicle weight (note that 3 gallons of gas weighs 19.5 lbs).

- A typical 0.5 kg laptop battery costs about 80$ - therefore 250 kg costs $10K

- Now let's remember ohms law. Power = VxI. A typical household standard 120V outlet has

a current rating of about 15 amps.

- 15 amps x 120 volts = 1.8 KW or 1.8 KWH per hour of charging

- Typical charging efficiency for PHEV is 85%

- To charge battery to 35 KWH from 120 volt source then requires 41 KWH to be delivered.

- @rate of 1.8 KWH per hour then this would take 41/1.8 = 22.8 Hours

- To charge "overnight" requires special circuitry installed - similar to a dryer circuit which

is 20 amps @220 volts of 4.4 KWH per hour thus reducing charging time by 1.8/4.4 or 9 hours.

Overall, there are three main problems associated with scaling up PHEVs to reduce overall

gas consumption.

1. Energy density storage of Li-Ion batteries is still insufficient relative to american long

distance driving habits - while much research is going into making more efficient batteries (e.g. Envia systems) this battery technology must be scalable - that is, it can't rely on rare materials and/or complex production processes. While you can make such batteries in your lab, that doesn't mean you can suddenly produce millions of battery packs.

2. There is a real potential problem with the lithium-ion supply chain and market demand. For instance, if there is a sudden

need for mass production of 500 lb lithium-ion battery packs then laptop battery production would likely have to go down. At the current limited rates of production, the supply chain should

sustain this yield: as said before, this yield will reach 3% market penetration by 2020 - while that might be great for business, it doesn't really do much to reduce the planetary GHG emissions associated with transportation.

3. The price of the battery pack raises the price of the vehicle significantly. (You can buy

3 Toyota Yaris's for the price of 1 Chevy Volt)

|