As of end of 2011 in the US there was only 1.9GW of installed CSP (compared to 40 GW of wind).

There are other CSP projects in the world but they too are not

yet cost effective.

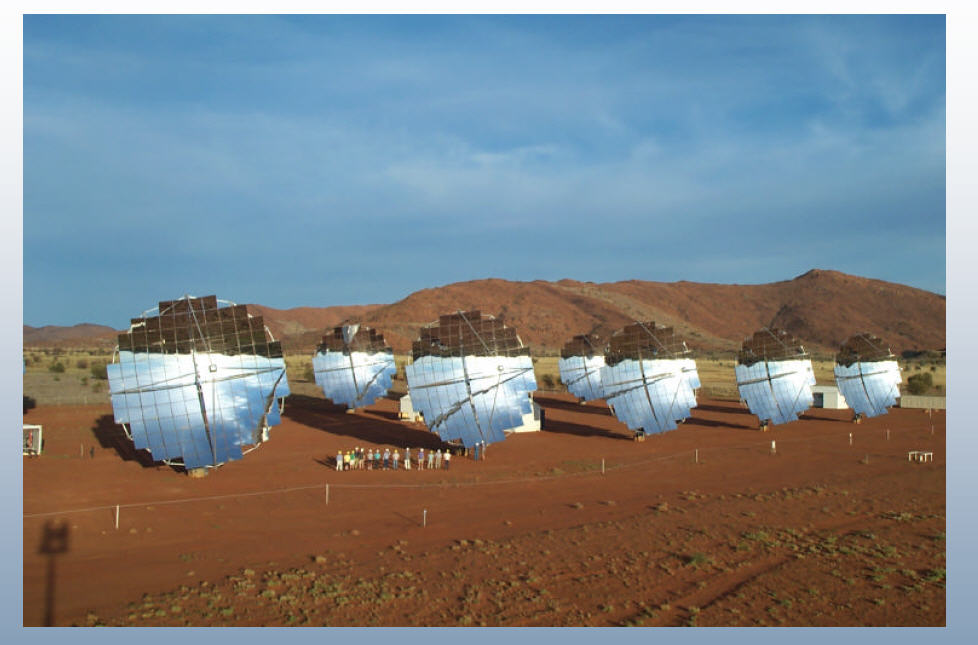

The issue then becomes the reliability of the CPV components over time. Also CPV systems function best under clear sky, direct-sun conditions. Early installations were made in Saudi Arabia, Arizona and at Alice Springs, Australia. Costs are a strong function of DNI (Direct Normal Irradiance):

Linear Fresnel Lens:

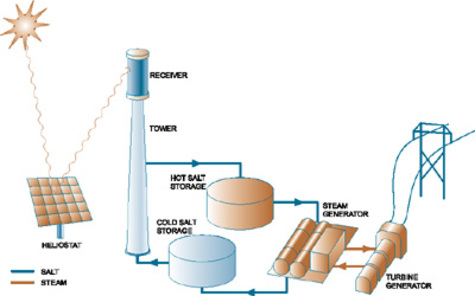

Advantage = simplest system and light weight. Focus is "horizontal" and not parabolic. Can be made Large or small  In this case a network of mirrors (heliostats) mostly surrounds a central tower. That reflected and focussed sunlight heats up some kind of receiver at the top of the tower. That hot liquid, usually molten salts, then mixes with water to make steam and hence electricity. This process is shown below.

One successful example of this is shown below for Chicago: The Urban Brownfield Array (chicago)

Before the installation

Many commercial systems now use something called a parabolic trough: Here the focus point of the parabolic trough is a receiver pipe. The pipe is filled

with oil (not crude oil) and is heated to about 400 C. This heat energy is then used to

generate electricity in a conventional steam generator. Solar trough farms are now being constructed (at a slow pace) in some locations in the American SW. The Nevada Solar One: plant is a good example of a small scale project Many commercial systems now use something called a parabolic trough: Here the focus point of the parabolic trough is a receiver pipe. The pipe is filled

with oil (not crude oil) and is heated to about 400 C. This heat energy is then used to

generate electricity in a conventional steam generator. Solar trough farms are now being constructed (at a slow pace) in some locations in the American SW. The Nevada Solar One: plant is a good example of a small scale project We can use the details of construction of Nevada Solar One as a model to scale from:

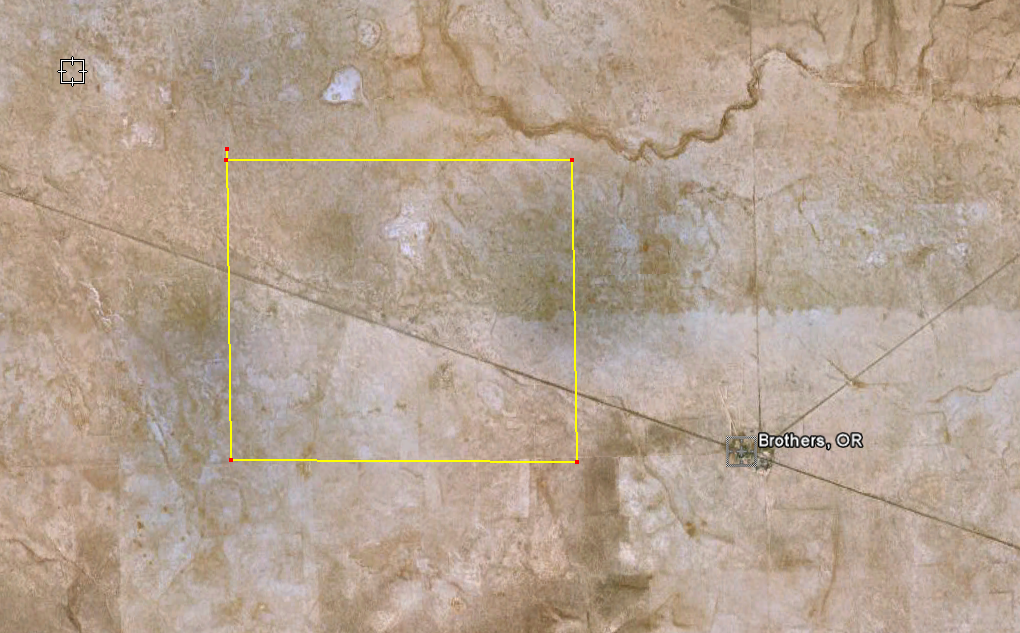

All renewable energy projects need to be evaluate in the units just presented! Now let imagine scaling this up by a factor of 10 to 640 MW to serve Eugene. What kind of footprint would that have in say a sunny location in Eastern Oregon?

If this facility had a 30 year lifetime, then that 2.7 billion dollar sticker shock is really $90 million dollars a yeaar for 30 years. Oregon already spends about 1 Billion dollars a year on core infrastructure projects so this is a drop in the bucket. Suppose you wanted to put the project cost entirely on Eugene residents. According to EWEB there are about 75,000 residential customers in Eugene. That translates into $1200 per year per residence to build this facility (from which each residence would get "free" electricity during the day time).

|

The primary potential problem here for any CSP system is heat load and subsquent failure

of either the PV material itself or one of the components in the optical path.

Within CPV systems, the concentration rato can have high variance.

If light that falls on 100 sq. cm of reflector surface is focussed onto a 1 sq. cm surface

of PV material, then the concentration ratio is 100. Current commercial design concentration

ratios are in the range 200-300 suns. Concentration ratios of more than 1000 have been produced by start up companies that

have claimed to "solve" the energy problem but those companies, like their components, quickly melted.

The primary potential problem here for any CSP system is heat load and subsquent failure

of either the PV material itself or one of the components in the optical path.

Within CPV systems, the concentration rato can have high variance.

If light that falls on 100 sq. cm of reflector surface is focussed onto a 1 sq. cm surface

of PV material, then the concentration ratio is 100. Current commercial design concentration

ratios are in the range 200-300 suns. Concentration ratios of more than 1000 have been produced by start up companies that

have claimed to "solve" the energy problem but those companies, like their components, quickly melted.