Biodiesel is a domestically produced, renewable fuel that can be manufactured from vegetable oils, animal fats, or recycled restaurant greases.

According to the American Biofuels Association, with government incentives comparable to those that have been provided for ethanol, biodiesel sales could reach about 2 billion gallons per year, or replace about 8% of conventional highway diesel fuel consumption.

It takes about 7.3 pounds of soybean oil, which costs about 20 cents per pound, to produce a gallon of biodiesel. Feedstock costs alone, therefore, are at least $1.50 per gallon of soy biodiesel.

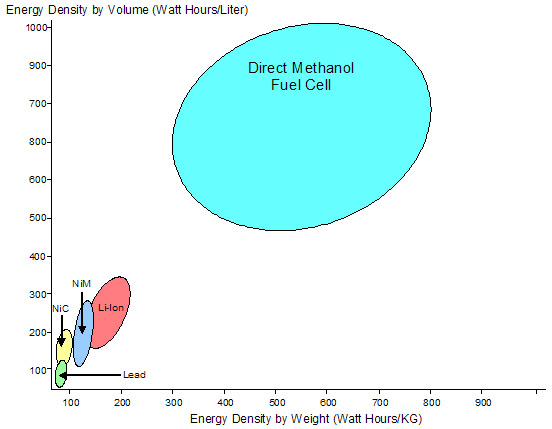

Clearly demands better energy storage batteries. There is a promising future here

Long Story Short:

The energy density storage of batteries (in units of Watt-Hours per Kilogram) is insufficient to power vehicles for long periods of time (> 2 hours).

The power density storage of batteries (in units of Watts per KG) is sufficiently high to deliver the required power. But, it can't deliver that power for very long.

Ethanol is an alcohol-based alternative fuel produced by fermenting and distilling starch crops that have been converted into simple sugars. Feedstocks for this fuel include corn, barley, and wheat

Today's commercially available vehicles that can use E85 (85% Ethanol and 15% gasoline) are called flexible fuel vehicles (or FFVs), meaning that they can run on E85, gasoline, or any mixture of the two.

More than 3 million FFVs have already been sold in the United States.

Most of the current E-85 fueling stations are located in the mid-west; however, there are approximately 150 E-85 fueling stations across the country.

Guess how many gasoline stations there are in the country.

Methanol, also known as wood alcohol, has been used as an alternative fuel in flexible fuel vehicles that run on M85 (a blend of 85% methanol and 15% gasoline).

Methanol Methanol, also known as wood alcohol, has been used as an alternative fuel in flexible fuel vehicles that run on M85 (a blend of 85% methanol and 15% gasoline). However, it is not commonly used as such because automakers are no longer supplying methanol-powered vehicles. Methanol can be used to make methyl tertiary-butyl ether (MTBE), an oxygenate which is blended with gasoline to enhance octane and create cleaner burning fuel. MTBE production and use has declined due to the fact that it has been found to contaminate ground water.

There are no longer any methanol vehicles available to purchase and there are no fueling stations available to the public. However, methanol has the potential of bridging the path to a hydrogen future. Methanol can be used to produce hydrogen and the methanol industry is working on technologies that would allow methanol to produce hydrogen for fuel cell vehicle applications.

Currently this is most sensible for commercial fleets that can fuel from a commercial available compressors.

For the individual, a compressor costs about $1000 and would take abou 8-10 hours to "refuel" a vehicle.

- Conventional ethanol is derived from grains such as corn and wheat or soybeans.

This has somewhat limited yield per unit acre of crops grown.

- Cellulosic ethanol can be produced from a wider variety of cellulosic biomass feedstocks including agricultural plant wastes (corn stover, cereal straws, sugarcane bagasse), plant wastes from industrial processes (sawdust, paper pulp) and energy crops grown specifically for fuel production, such as switchgrass

Promise lies in the following:

Cellulosic ethanol production substitutes biomass for fossil fuels, changing the emissions calculations, according to Michael Wang of Argonne National Laboratories. Wang has created a "Well to Wheel" (WTW) life cycle analysis model to calculate greenhouse gas emissions produced by fuels in internal combustion engines. Life cycle analyses look at the environmental impact of a product from its inception to the end of its useful life.

"The WTW model for cellulosic ethanol showed greenhouse gas emission reductions of about 80% [over gasoline]," said Wang. "Corn ethanol showed 20 to 30% reductions." Cellulosic ethanol's favorable profile stems from using lignin, a biomass by-product of the conversion operation, to fuel the process. "Lignin is a renewable fuel with no net greenhouse gas emissions," explains Wang. "Greenhouse gases produced by the combustion of biomass are offset by the CO2 absorbed by the biomass as it grows."

Read Michael Wang's Presentation. Its very informative

Note that large scale biomass production for alternative fuels potentially creates a lot of jobs.

Developing a comparative index. The higher the number the better.