Biodiesel:

Biodiesel is a domestically produced, renewable fuel

that can be manufactured from vegetable oils,

animal fats, or recycled restaurant greases.

Highest yields come from:

It takes about 7.3 pounds of

soybean oil, which costs about 20 cents per pound,

to produce a gallon of biodiesel. Feedstock costs

alone, therefore, are at least $1.50 per gallon of soy

biodiesel.

Total possible yield:

- There are about 360 million acres of useable crop land in the US.

- One acre of land produces an average of 40 bushels of soybeans.

- Each bushel of soybeans can produce about 1.5 gallons of soybean oil.

- Efficiency of conversion of soybean oil to right chemical formula for

fuel in an engine: about 80%

Multiplying everything together gets you 18 billion gallons a year (remember

we need 150) and this would require all crop land devoted to growing fuel

and not food for a resultant 12% market penetration.

Electricity (e.g. Plugin Hybrid Electric Vehicles - PHEV)

A brief primer on important numbers:

- You will see numbers ranging from 33 to 37 KWH energy equivalent to a gallon of gasoline.

The variation is related to whether you do the calculation by mass or by volume since the

volume of gallon of gas is temperature dependent. In round numbers there are 35 KWH per gallon of

gas.

- Suppose average fuel economy rises to 35 miles per gallon (for a 3000 lb car)

This is

then equivalent to 1 KWH per mile energy cost. This is a useful number to know.

This is

then equivalent to 1 KWH per mile energy cost. This is a useful number to know.

- But, an electric motor is about 2.8 times more efficient than an ICE and therefore

the per mile electricity cost equivalent is about 0.35 KWH per mile.

- A lithium-ion battery pack stores an average of 140 watt hours per kg. Typical laptop battery

weighs about 1 kg and average laptop power consumption is about 40 watts. This means

your laptop battery lasts for 140 watt hours/40 watts = 3.5 hours. At peak power your laptop

likely consumes 80 watts and so the battery lifetime would he halved.

- Suppose you want 100 mile free range (such as the Nissan leaf "claims") on your lithium-ion

battery pack. @0.35 KWH per mile you would then need to store 35 KWH of electricity: @140

watt hours per kg (.14 KWH per kg) you would need 35/.14 = 250 kg (550 lb) battery pack -

a significant fraction of total vehicle weight (note that 3 gallons of gas weighs 19.5 lbs).

- A typical 0.5 kg laptop battery costs about 80$ - therefore 250 kg costs $10K

- Now let's remember ohms law. Power = VxI. A typical household standard 120V outlet has

a current rating of about 15 amps.

- 15 amps x 120 volts = 1.8 KW or 1.8 KWH per hour of charging

- Typical charging efficiency for PHEV is 85%

- To charge battery to 35 KWH from 120 volt source then requires 41 KWH to be delivered.

- @rate of 1.8 KWH per hour then this would take 41/1.8 = 22.8 Hours

- To charge "overnight" requires special circuitry installed - similar to a dryer circuit which

is 20 amps @220 volts of 4.4 KWH per hour thus reducing charging time by 1.8/4.4 or 9 hours ...

So there are three main problems associated with scaling up PHEVs to reduce overall

gas consumption.

1. Energy density storage of batteries is still insufficient relative to american long

distance driving habits (much research is going into making for efficient batteries and

we will discuss energy storage later in this course).

2. There is a real potential problem with the lithium-ion supply chain ( which

causes significant scalability problems ) if there is a sudden

need for mass production of 500 lb lithium-ion battery packs.

3. The price of the battery pack raises the price of the vehicle significantly. (You can buy

3 Toyota Yaris's for the price of 1 Chevy Volt)

Grain-Based Ethanol:

Ethanol is an alcohol-based alternative fuel

produced by fermenting and distilling starch crops

that have been converted into simple sugars.

Feedstocks for this fuel include corn, barley, and

wheat

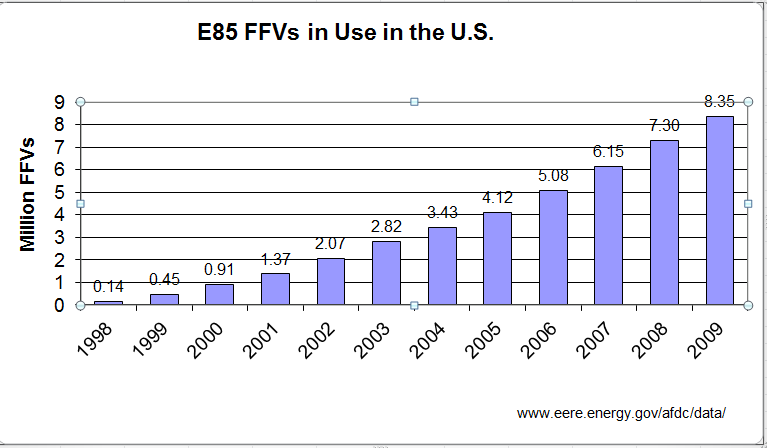

Today's commercially available vehicles that can use

E85 (85% Ethanol and 15% gasoline) are called

flexible fuel vehicles (or FFVs), meaning that they

can run on E85, gasoline, or any mixture of the two.

About 10-12 million (our of 300-500 million)

FFVs have already been sold in the

United States.

Most of the current E-85 fueling stations are located

in the mid-west; however, there are approximately

1600 E-85 fueling stations across the country. In the case of Shell oil,

you will get 10% ethanol whether your want it or not.

Sequential BioFuels is located in

Eugene and is a local distributor of biodiesel and grain ethanol fuels.

But grain based ethanol is simply not scalable (as will be

shown shortly)

Fuel Cells:

- Hydrogen production comes from stranded renewables (i.e. wind energy in the

Aleutian Islands) or maybe from new NG sources.

- Honda FCX is a real car

- Hydrogen has higher energy density than gasoline so no performance issues at all.

- Current limiting factor on scalability is the required platinum catalyst as previously

explained.

Cellulostic BioFuels. This may have large potential:

- Conventional ethanol is derived from grains such as corn and wheat or soybeans.

This has somewhat limited yield per unit acre of crops grown.

- Cellulosic ethanol can be produced from a wider variety of cellulosic biomass feedstocks including agricultural plant wastes (corn stover, cereal straws, sugarcane bagasse), plant wastes from industrial processes (sawdust, paper pulp) and energy crops grown specifically for fuel production, such as switchgrass

Overall Ethanol Production Scheme

Notes:

- large scale biomass production for alternative fuels potentially creates

a lot of jobs

- The major technical/scientific problem is sugar extraction with reasonable efficiency.

This is why Sugar Cane is the best feedstock (e.g. Brazil). The current efficiency from

converting pretreated cellulosic material into sugar is very low. With R&D investment,

this can increase and it has to in order to cellulosic ethanol to become a serious fuel source.

Natural Gas: Potentially feasible if the cost of electricity associated with compressing

the gas for storage in a vehicle is reasonable.

Developing a comparative index. The higher the number the better.

AFI = Fuels Index:

- Alternative Fuels Index (AFI) = weights P and G

- Renewable Fuels Index (RFI) = weights F and G

G = percentage reduction in greenhouse gas emissions; common to both indexes

P = percentage reduction in actual petroleum use. This is what "alternative" means. Alternatives

to petroleum

F = percentage change in total fossil fuel usage (including fossil energy/electicity to make

the fuel).

Clear winners are:

- Hydrogen from stranded renewables (this is equivalent to H with all C sequestered)

- E85 from cullulostic sources (not achieveable yet)

This is

then equivalent to 1 KWH per mile energy cost. This is a useful number to know.

This is

then equivalent to 1 KWH per mile energy cost. This is a useful number to know.