Ethanol has long been a viable substitute for gasoline fuel. However, the energy content of Ethanol is 10-20% lower than gasoline and consequently fuel economy will be lowered by 10-20% when using a strictly ethanol bases fuel. Indeed, in many states (including Oregon) most of the "gasoline" you buy at the pump has some amount of ethanol already mixed in.

A definitive guide to all things BioFuel

Ethanol comes from two kinds of feedstocks a) Grain and b)the whole plant (cellulosic)

Grain-Based Ethanol:

Ethanol is an alcohol-based alternative fuel

produced by fermenting and distilling starch crops

that have been converted into simple sugars.

Feedstocks for this fuel include corn, barley, and

wheat

Today's commercially available vehicles that can use

E85 (85% Ethanol and 15% gasoline) are called

flexible fuel vehicles (or FFVs), meaning that they

can run on E85, gasoline, or any mixture of the two.

FFVs are quite

common today and you may even own one and not know it.

In 2011 there were estimated to be about 14 million FFV vehicles on the road. While this sounds impressive, there are at least 300 million total vehicles in the US alone and 10 million is 4.5% of that total.

Most of the current E-85 fueling stations are located

in the mid-west; however, there are approximately

3000 E-85 fueling stations across the country. In the case of Shell oil,

you will get 10% ethanol whether your want it or not.

Sequential BioFuels is located in

Eugene and is a local distributor of biodiesel and grain ethanol fuels.

But grain based ethanol, as derived from US Corn growth, is simply not scalable (as will be

shown shortly) and will be relegated to local markets mostly located in the Midwest.

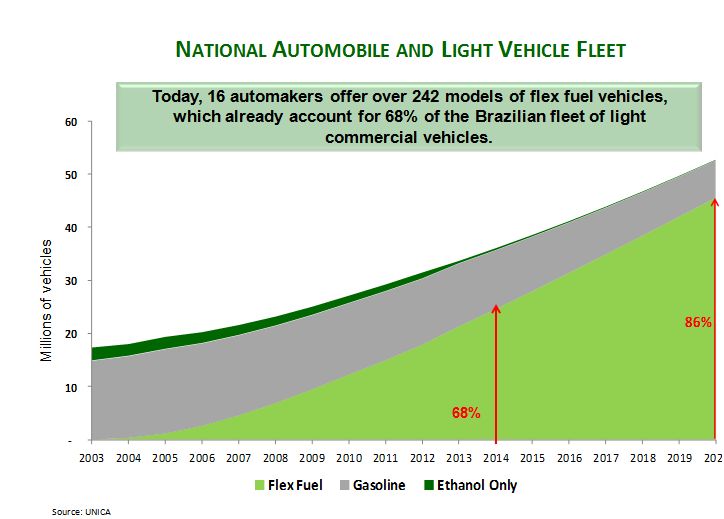

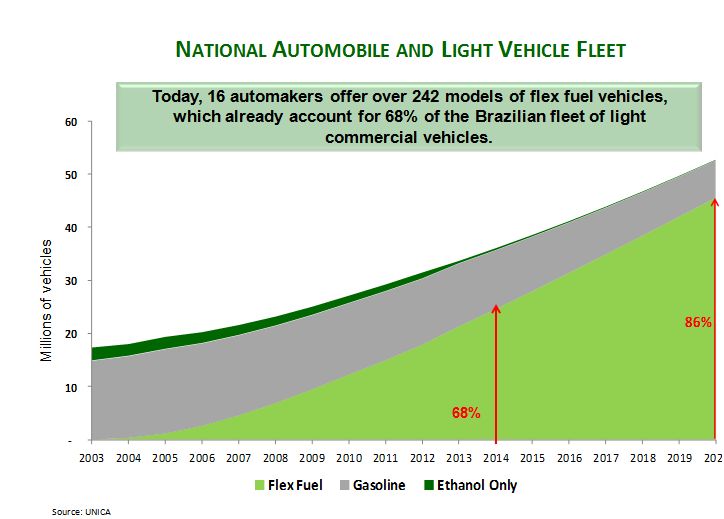

A promising source of ethanol based transportation does come from sugar cane. Brazil is a major producer of sugar gain and now has an aggressive initiative to change out most of their transportation fleet from gasoline/diesel based to sugar cane based. The market response in terms of sales of FFVs in Brazil

has been phenomenal, as shown below, and Brazil is well on their way to achieving this goal.

Cellulostic BioFuels: this may have large potential:

- Conventional ethanol is derived from grains such as corn and wheat or soybeans.

This has somewhat limited yield per unit acre of crops grown.

- Cellulosic ethanol can be produced from a wider variety of cellulosic biomass feedstocks including agricultural plant wastes (corn stover, cereal straws, sugarcane bagasse), plant wastes from industrial processes (sawdust, paper pulp) and energy crops grown specifically for fuel production, such as switchgrass

Overall Ethanol Production Scheme

Notes:

- large scale biomass production for alternative fuels potentially creates

a lot of jobs

- The major technical/scientific problem is sugar extraction with reasonable efficiency.

This is why Sugar Cane is the best feedstock (e.g. Brazil). The current efficiency from

converting pretreated cellulosic material into sugar is very low. With R&D investment,

this can increase and it has to in order to cellulosic ethanol to become a serious fuel source.

Details on the Potential Yield of Cellulosic Ethanol:

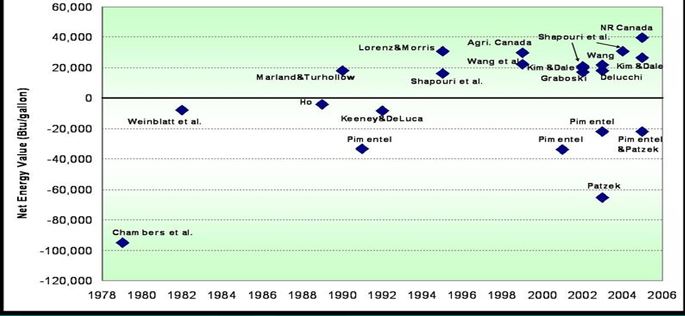

The overall net energy gain of ethanol has been a source of intense research for 3 decades. Ethanol opponents are quick to say that it takes more energy to make ethanol than you get out of it. That statement, was once true, about 30 years ago. Most people never evolve their opinion once it has formed and never pay much attention to advances in the field, since they have already formulted the truth.

The figure below shows how the evolution of the net energy ratio over time and a definitive 2008 report concluded that the net energy gain

was 2.3. Some studies have even found energy gains as large as a

factor of 5.

Among things that you should know when this course is complete is that the production of ethanol is a POSITIVE net energy gain

So now let's consider some yield scenarios for both grain baised and cellulosic based ethanol - keeping in mind that annual fuel use is 150 billion gallons of gasoline. Note that a gallon of ethanol has about 75% the energy content of gasoline at standard room temperature. Therefore 150 billion gallons of gasoline is equivalent to 200 billion gallons of ethanol.

Grain Based Scenario:

- 10 Kg of corn produce 1 gallon of grain based ethanol

- 1 Ideal acre of corn produces 850 gallons

- We assume that 1 real world acre of corn is 2/3 of the ideal acre or 570 gallons per acre

- Required acreage to meet this 200 billion gallons goal would then be 350 million acres on which to grow corn

is this is a little or a lot? is this is a little or a lot?

- The most recent acreage report is HERE . According to that report, there are 90- 100 million acres on which corn was planted, well short of the required 350 million acres. So, grain based ethanol

does not scale.

And of course, you can not devote all of the 95 million acres to growing corn for fuel. The maximum mix is likely 75% for food and 25% for fuel bringing you down to about 25/350 = 7% market penetration with corn feed grain based ethanol.

The Promise of Cellulosic Ethanol: 100 Billion gallons

Switchgrass is a common prarie grass that grows in dense

and high bundles and is an ideal feedstock for cellulosic

ethanol. Potentially vast areas of Canada could be seeded with

switchgrass for fuel which is a hell of a lot better than currently using Canadian tar sands for gasoline.

- Current average yields for switch grass are 5--10 dry tons per acre.

- With improved breeding and cultivating techniques

yields approachin 15 dry tons per acre may be possible. Indeed, a recent

experiment done at UC Davis has produced 17.6 tons per acre

- To produce the target goal of 100 billion gallons (meaning

market penetration of 50%) would require 88 Million acres dedicated to growing switch grass.

- For context, currently 83 million acres are dedicated to growing soybeans for animal feed and switchgrass has more animal protein per unit mass than soybeans. Thus there are two markets

for switchgrass: pet food and fuel.

- The production costs of have been estimated to range

from 60-90 cents per gallon and a more recent and very comprehensive

study supports these production costs

- These production costs are less than crude oil costs and this will continue into the future. For reference, if crude oil

is at $100 per barrel then the production cost of gasoline is 100/42 = $2.38 per gallon.

So a realistic scenario based on the above information is:

- By the year 2030 fuel economy will improve to an average of 50 mpg**.

- Switchgrass yields will be 15 tons per acre

- 10% of available cropland will be dedicated to growing switch grass.

- 1/2 of all vehicles can now be powered by switchgrass. Wow - this could actually be done, if we just decided to do it. This effort, at the national scale, would also create a lot of jobs.

**note: increased fuel economy is essential no matter what fuel is under consideration.

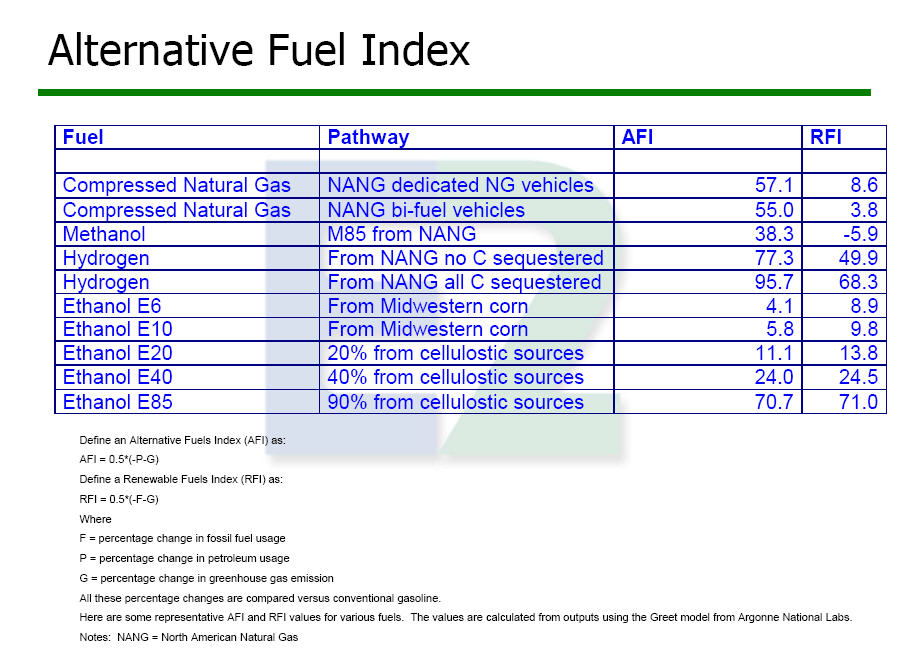

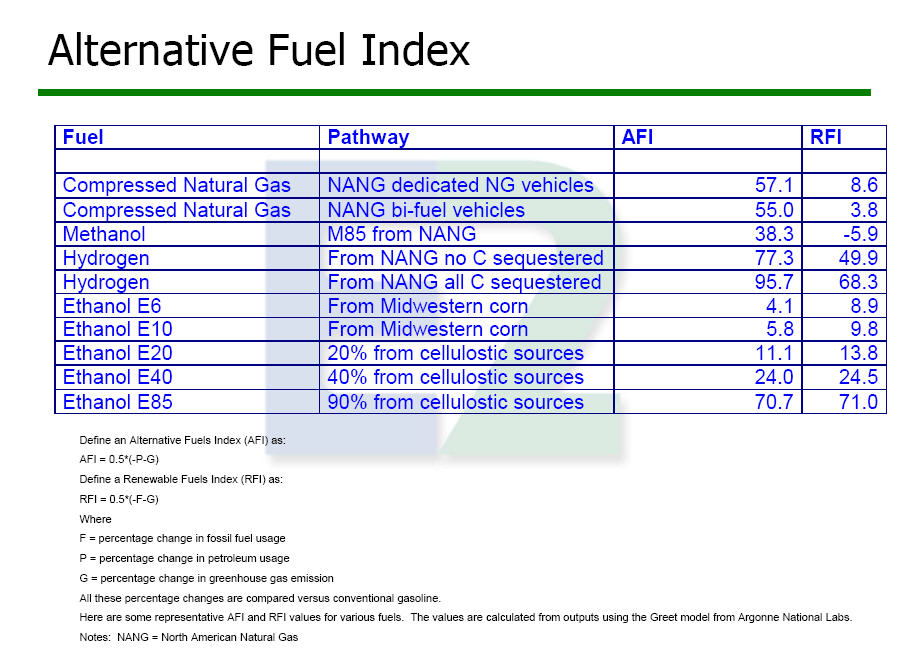

Finally, there are attempts to develop various kinds of environmental indices to determine which kind of fuel mixes

have the most impact. An example is shown below. The higher the index number the better. There are three impact variables to consider: a) which fuel mix results in the lowest total greenhouse gas emissions (G); b) which fuel mix represents real

reductions in actual petroleum use (P); c) which fuel mixes produce

the largest changes in total fossil usage (including the fossil inputs to make the fuel) (F). While interrelated, each of these are different goals to achieve.

The table below summarizes

- Alternative Fuels Index (AFI) = weights P and G

- Renewable Fuels Index (RFI) = weights F and G

for various fuel considerations. In most cases

the AFI and the RFI are not well correlated.

Let's go through these results:

- NANG = North American Natural Gas (e.g. fracking) and the production of NG powered vehicles (which now are mostly busses). This technology scores well in terms of reducing greenhouse gas emissions relative to gasoline as well as directly reducing crude oil usage. However, the RFI is low because a) this is still a fossil fuel and b) a lot of fossil based energy input is required to compress NG so it can be used as a fuel.

- Methanol is now deemed too toxic and its use has been discontinued.

- E85, from cellusoic sources, has both very high AFI and RFI and therefore accomplishes all three goals of reducing ghg emissions, reducing crude oil use, and lowering fossil use.

- Hydrogen: this will be discussed in more detail later. The above table assumes Hydrogen would be made via its current process, steam reformation of CH4 (natural gas) - but

this is necessarily true now. In any event, the biggest winner

in the table above is achieved when the Carbon is sequestered in the steam reformation process.

In general, this process of producing index scores so that technologies can be compared in a relative sense, can be a very important input into policy. For instance, from the above table

it would seem foolish to invest in NG powered vehicles and foolsing to invest in Ethanol at any level less than E85.

Moreover, two viable solutions arise: E85 and Hydrogen as long

as the Carbon is sequestered. We will see later that producing

Hydrogen from OFF shore wind facilities maybe a very good thing

to pursue.

|

is this is a little or a lot?

is this is a little or a lot?